Extrusion Processes

Project goal

The goal of lowering the energy consumption for heating buildings has led to an increasing demand for insulation materials for buildings. These materials include insulation panels made from extruded polymers such as polystyrene (XPS). These insulation boards are foamed during an extrusion process using carbon dioxide as a blowing agent. The resulting foam consists mainly of relatively small closed cells and thus has advantageous properties in terms of mechanical strength and thermal conductivity.

Due to variations in the extrusion process, however, the insulation boards produced can also vary considerably and the desired mechanical and thermal properties cannot be obtained. It is therefore necessary to continuously monitor the extrusion process by determining the desired quality measures, i.e. H. Mechanical strength and conductivity of the insulation boards produced are determined. This is currently done mainly by taking samples from the production line and performing laboratory experiments on these samples to determine the quality parameters.

Since the aging of the material has a significant influence on the quality parameters, the laboratory tests can only be carried out after a certain period of time has elapsed since the sampling. Therefore, the entire batch produced in the meantime may have to be thrown away if laboratory tests show that the production process did not run properly.

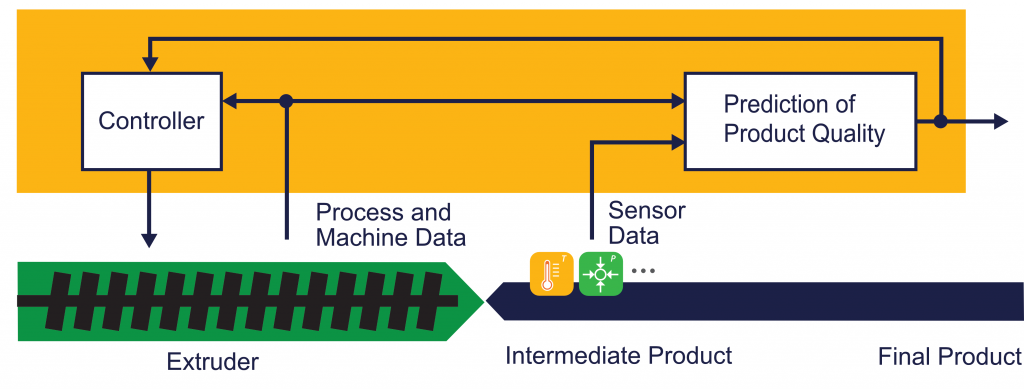

Knowtion is part of a BMBF research group, the aim of which is to detect such production losses earlier and more precisely by directly measuring product properties with which the critical quality parameters can be predicted. This improves the detection accuracy, reduces the time required for detecting defects, and thus also reduces the amount of scrap generated.

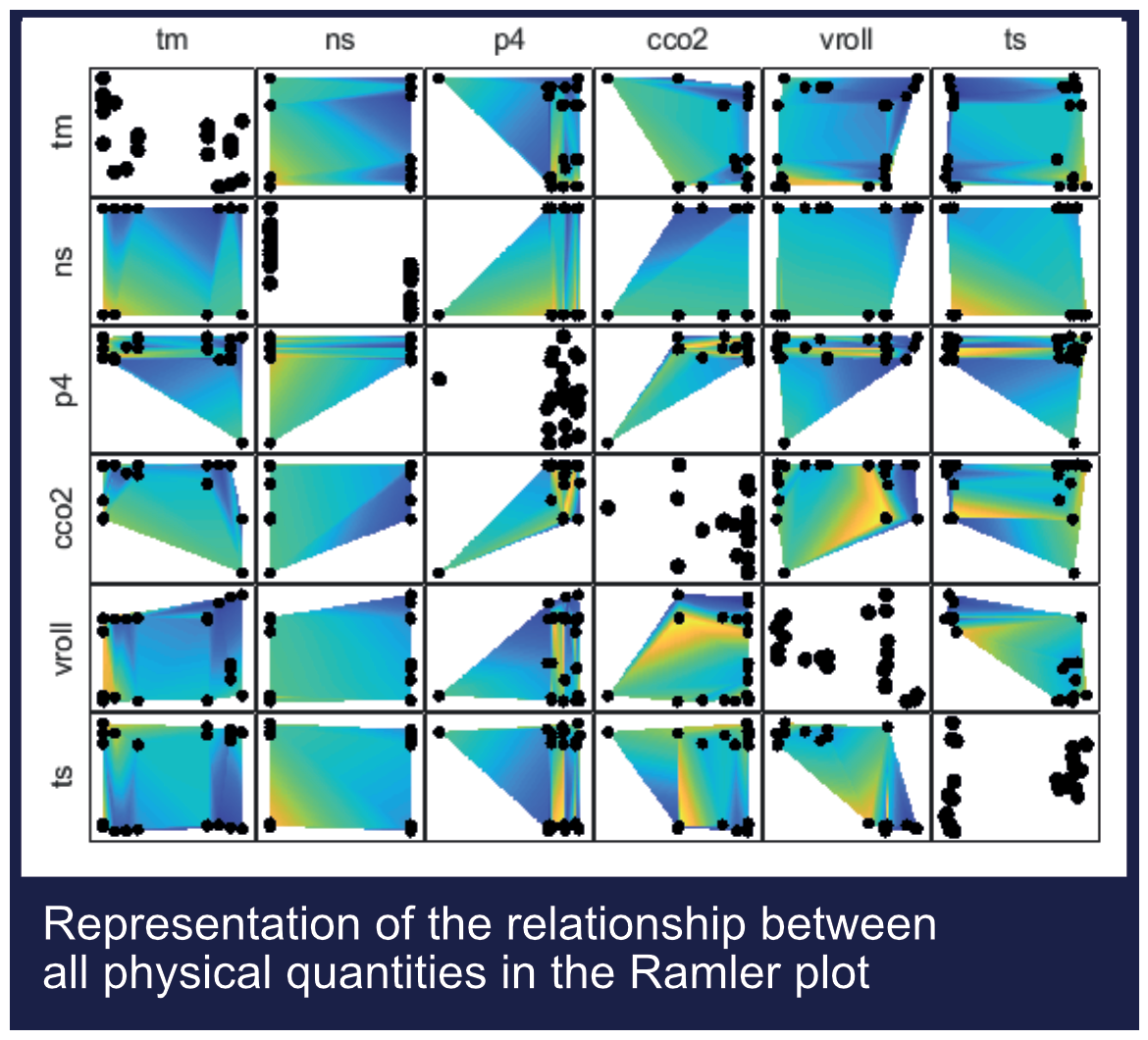

For this purpose, sensor values for pressures, temperatures and material flows are used, which are supplied by sensors directly attached to the machine, in order to monitor the operating status of the extruder and to detect internal errors. In addition, an acoustic sensor, a dielectric sensor and a thermal conductivity sensor are placed in the production line to measure the material properties of the freshly foamed insulation boards.

Procedure and solution

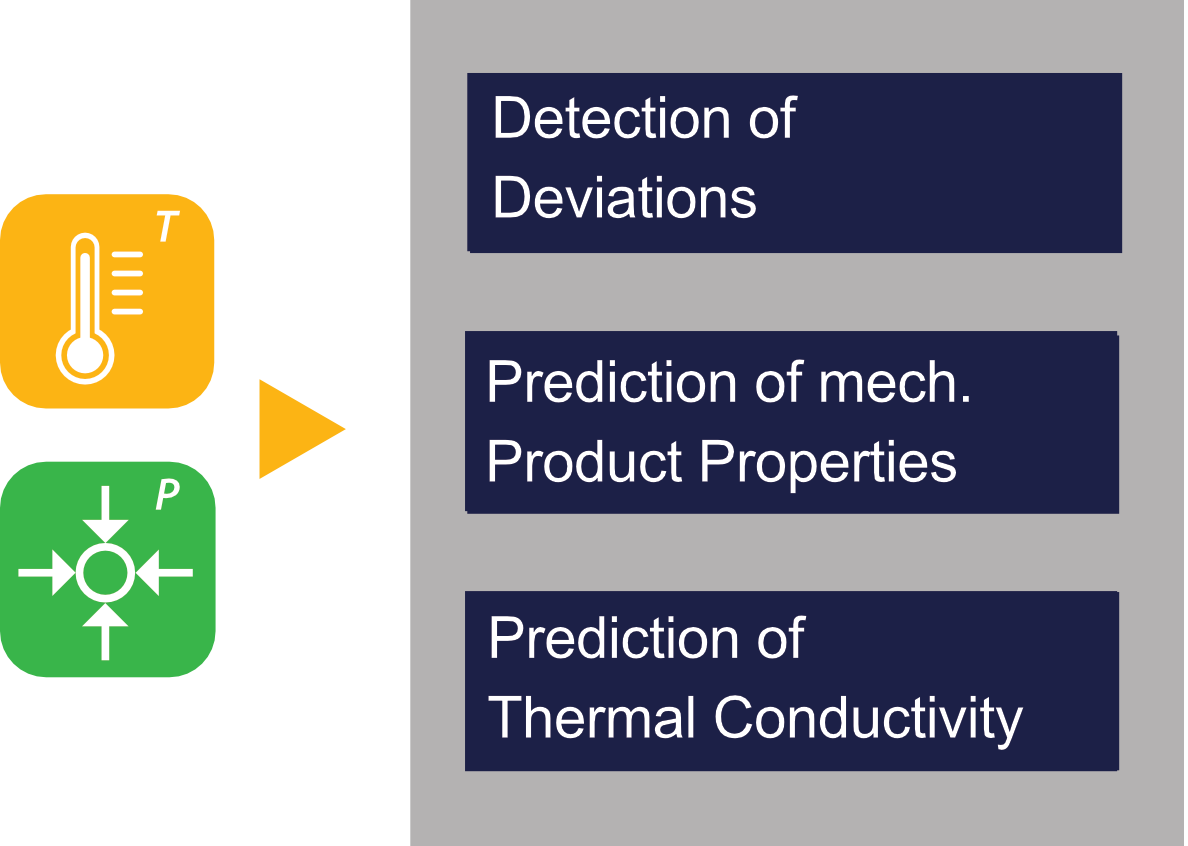

Detection of deviations from the expected working method using an extruder model specially developed for this project. The extruder model uses sensor values for pressures, temperatures and material flow, which are provided by sensors attached directly to the machine.

Prediction of the mechanical product properties (density, compressive strength and compressive rigidity) on the basis of dielectric and acoustic sensor measurements.

Prediction of the thermal conductivity based on the predicted material properties and a novel thermal conductivity sensor developed by one of our project partners.

Result and benefit